UPCYCLING PLASTIC STRAWS

Plastic straws are the most widely used, and therefore disposed of after single use. Many types of straws cannot be reused due to the chemicals they are made from or recycled causing environmental depletion. Its affordability and water resilient property makes it almost impossible to replace.

So this project aimed at exploring the other unique properties of straws such as porosity, light weight, slipperiness, cushiony/rounded, strong, etc. through interlacing structures on loom. Various material and weaving technique combinations are used to make sample surfaces without changing the chemical properties giving them a sustaining second life.

Sample 1-

Weave- Honeycomb

Warp- straw

Weft- Sturdy metal wires

Concept- Combination of woven sturdy wires and straws forming big and strong honeycomb unit (6”x 2”) structure.

Warp- straw

Weft- Sturdy metal wires

Concept- Combination of woven sturdy wires and straws forming big and strong honeycomb unit (6”x 2”) structure.

Sample 2-

Technique- Double Cloth (plane weave)

Warp- straw (3 metal wires inserted between the straws)

Weft- straw

Concept- The bottom layer is not woven after a point. So that the top layer can bend and give a shed to it.

Sample 3-

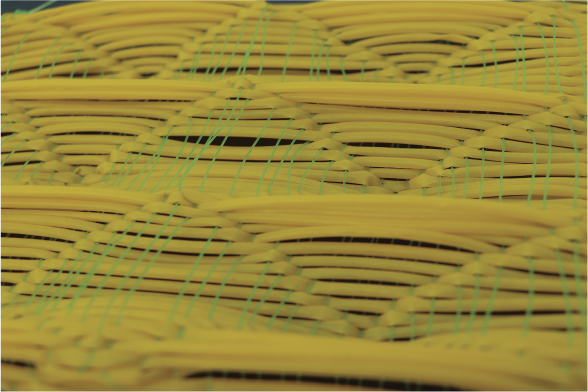

Technique- Double Cloth (honeycomb+ plane)

Warp- straw (metal wires inserted at the topmost layer of honeycomb)

Weft- straw (metal wires inserted at the topmost layer of honeycomb)

Concept- Metal frame forms perfect rectangular units with evident depth to each unit. The bottom layer acts as a supporting layer to the units.

Sample 4-

Weave- Honeycomb

Warp- straw

Weft- nylon

Concept- Bigger honeycomb units gives a significant hight to the sample. Thin nylon weft tends to hold the structure together.

2 weeks, Personal project (2019)