3D WEAVING

3D WEAVING

Weaving is an age old craft with its diverse application in the clothing industry. This project aims to understand and explore techniques and structural possibilities of weaving in the third dimension. Combination of conventional and unconventional materials are used to get the superior property for the potential application.

Combining different materials intimately by Interlacing can have great strength and durability which gives rise to a whole new set of properties. Preformed multi-layer 3D wovens can be produced on existing infrastructure without any further investments. By planning the end use, the major part of the product can be woven into complex forms and geometry which will cut down the external cost, material and labor requirement in the making of a product.

Combining different materials intimately by Interlacing can have great strength and durability which gives rise to a whole new set of properties. Preformed multi-layer 3D wovens can be produced on existing infrastructure without any further investments. By planning the end use, the major part of the product can be woven into complex forms and geometry which will cut down the external cost, material and labor requirement in the making of a product.

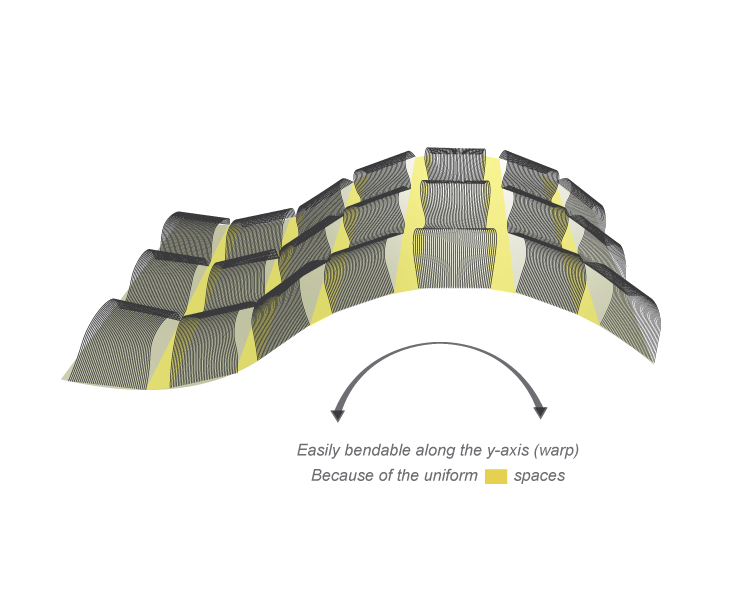

Sample 1

Pleating using contrasting materials - where the bulging extra warp (Nylon) keeps the sample stiff and sturdy along the length -x-axis. The spacing between the bulges makes it bendable along the width -y axis. Each bulging unit comes back to the original state as the restoring force acting upon it brings it back to equilibrium.

This can serve like a protective surface covering the product from all around if the units are made smaller and closely packed.

Structure Upon Action-

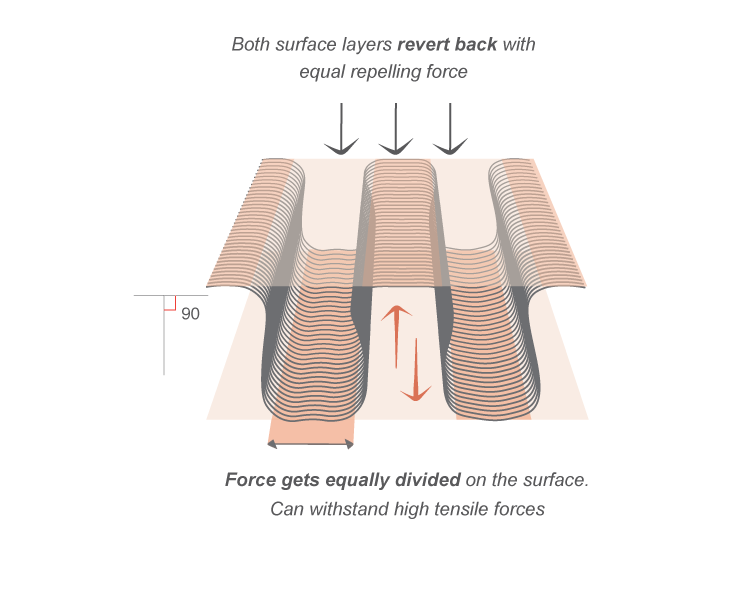

Sample 2

Pleated extra warp is sandwiched between two layers of the fabric. In this sample the sandwiched nylon layer is woven together/ separated by two woven cloth layers. So even under high tensile forces, the layers remains separated by right angles.

This can have a great potential in the packaging and large scale shock absorbing industry because of its structural stability at higher machanical stress

Structure Upon Action-

Sample 3

Extra warp is sandwiched between the two layers of fabric. Each intersecting unit is bound between the layers of cloth at a uniform distance. It gives even cushioning when compressed/force acts upon it.

This sample can be used as a better and harmless cushioning alternative (forces acting for longer period). This can have a great potential in the cushioning and mattress industry.

Structure Upon Action-

Sample 4

Where multiple layers of cloth can be woven together at the same time. This sample is woven with two contrasting materials (i.e, thread and wire) and bound along the edges creating a hollow space inside. The whole structure is collapsible.

This sample can have great applications in large scale as it’s easily portable where the space can be made and managed efficiently.

Structure Upon Action-

4 Weeks, Self initiated project (Academic) 2019

Guide- Arnab Senapati & Ram Mattegunta